- Robotic packaging systems enhance efficiency and precision in various industries.

- Flexibility and scalability are key advantages of these automated systems.

- Adoption of robotics in packaging leads to significant cost and labor savings.

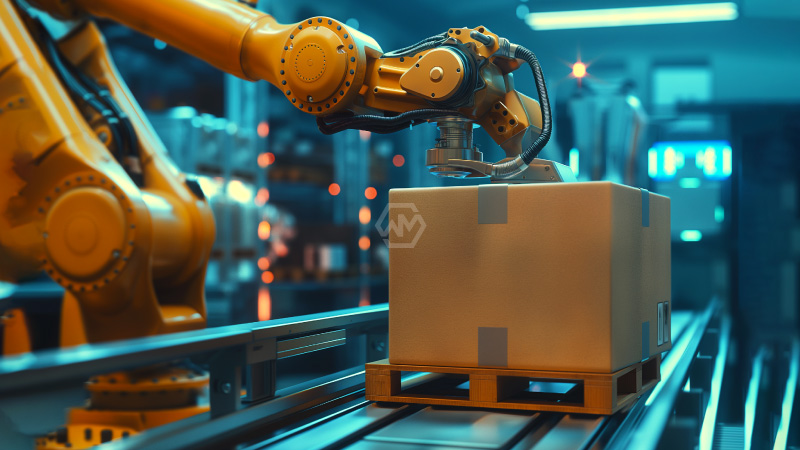

Robotic packaging systems have become a transformative force in the packaging industry, streamlining operations through automation. These systems, which include pick-and-place robots, case packing, and palletizing robots, are designed to handle diverse products with exceptional speed and precision.

Beyond efficiency, the flexibility of robotic packaging systems makes them adaptable to varying production needs. As businesses grow and product lines expand, these systems can be reconfigured to accommodate new packaging types and sizes.

The Future of Packaging: How Robotics Are Changing the Game

The integration of robotics into the packaging industry is not just about automating processes—it’s about redefining how businesses operate. Robotic packaging systems can work around the clock, handling high volumes of products without the need for breaks, thereby drastically increasing production output. This constant operation reduces cycle times, allowing companies to meet growing demand more efficiently than ever before.

Safety is another critical advantage that robotic packaging systems bring to the table. In environments where handling hazardous materials or working in unsafe conditions is required, robots can perform these tasks without risking human health. This shift not only enhances workplace safety but also ensures that production continues smoothly in challenging conditions.

Robotic packaging systems also excel in precision and consistency. Unlike human workers, robots can repeat the same task with exacting accuracy, ensuring that every product is handled and packaged to the same high standard. This precision reduces waste, minimizes the risk of damaged goods, and maintains the integrity of the packaging process.

Furthermore, the adaptability of robotic systems means they can easily transition between different product lines or packaging types, making them a versatile tool for companies looking to innovate. As consumer demands evolve, businesses can rely on these systems to quickly adapt, ensuring they remain agile and responsive in a competitive market.

As robotic packaging systems continue to evolve, they offer businesses unparalleled opportunities to optimize their operations. By embracing these technologies, companies can achieve greater efficiency, flexibility, and safety, ensuring they stay ahead in an increasingly automated world.

“Automation is going to cause unemployment, and we need to prepare for it.” — Mark Cuban