- LLNL researchers developed a computational framework to analyze the relationship between microstructure features and material properties.

- The framework combines physics-based modeling, feature extraction, and machine learning to study polymer-based porous materials.

- This approach aims to optimize material performance by understanding how microstructure influences properties like transport efficiency.

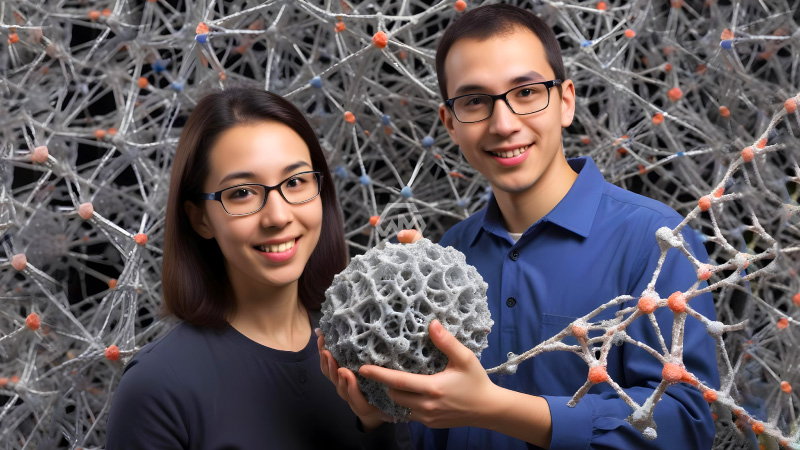

Lawrence Livermore National Laboratory (LLNL) scientists have introduced an innovative computational framework designed to unravel the complexities of porous microstructures and their properties.

This new framework integrates physics-based modeling with advanced machine learning tools to analyze how various microstructural features—such as domain and pore size—affect material characteristics.

LLNL’s New Tool Unveils Porous Polymer Secrets

Applying this framework to polymer-based porous materials has revealed insights into how polymerization dynamics affect these microstructural features. By understanding these effects, the framework can predict how changes in microstructure impact critical properties like transport efficiency. This capability is crucial for optimizing the performance of polymeric materials used in various applications, including membranes.

The ability to analyze and predict these relationships facilitates the design of materials with specific properties tailored to meet diverse application needs. Researchers can now guide processing methods to achieve desired characteristics, potentially revolutionizing the development of advanced materials.

This framework represents a significant step forward in material science, offering a detailed understanding of microstructure-property relationships. It has the potential to drive innovations in the design and application of high-performance materials across multiple industries.

This novel computational framework not only advances the understanding of how microstructures influence material properties but also sets the stage for future innovations in material design. By integrating multiple analytical tools, researchers can now tailor materials with precision to meet specific performance criteria, potentially transforming various industrial applications.

“We have developed an integrated computational framework which incorporates physics-based microstructure modeling, microstructure